We are Manufacturer, Supplier, Exporter of Perforated Cable Trays, Pre Galvanized Perforated Cable Trays, GI ( Galvanized Iron) Perforated Cable Trays, Hot Dip Galvanized Perforated Cable Trays, Powder Coated Perforated Cable Trays and Our Setup Situated in Pune, Maharashtra, India.

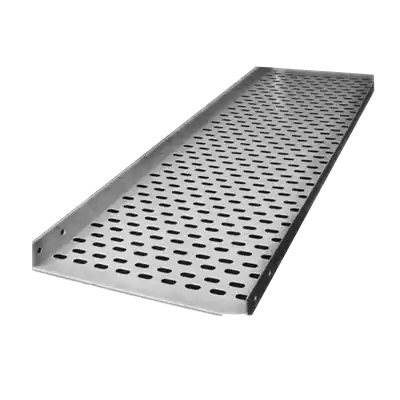

Perforated Cable Trays can accommodate a large number of branch lines and have high load-bearing capacity. They can be hung or mounted on the wall. They are available with covers.

|

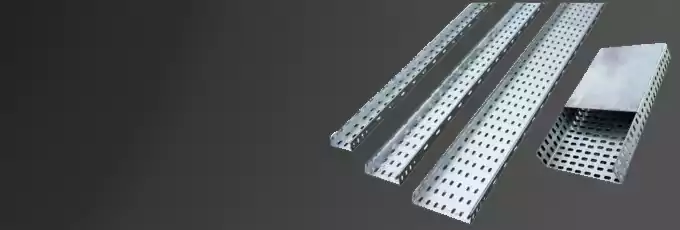

Standard Length |

2500 mm, 3000 mm |

|

Thickness |

1.2 mm to 2 mm |

|

Height |

25 mm, 50 mm, 75 mm |

|

Width |

50 mm, 75 mm, 100 mm, 150 mm, 200 mm, 250 mm, 300 mm, 350 mm, 400 mm, 450 mm, 500 mm & above 600 mm |

|

Finish |

Pre-Galvanized, G.I. Hot Dip. and Powder Coated. |

Perforated Type Cable Trays:

- These are specialized support systems designed for the safe and efficient management of electrical cables in various industries.

- They are made from high-quality materials such as SS (Stainless Steel), GI (Galvanized Iron), and Aluminum to ensure long-term durability and resistance to environmental factors.

- The perforations in these trays provide excellent ventilation, preventing heat accumulation and ensuring proper airflow around the cables.

- These trays are also easy to install and maintain, making them a popular choice in modern electrical installations.

GI Perforated Cable Trays (Galvanized Perforated Cable Trays):

Salient Features:

Applications:

- These are highly durable and corrosion-resistant cable management solutions made from galvanized iron (GI).

- The perforations in these trays allow for improved ventilation and airflow, preventing heat buildup around electrical cables.

- Designed to support and organize cables efficiently, these trays are widely used in electrical and industrial installations.

- The galvanized finish ensures long-lasting protection against corrosion, making them suitable for both indoor and outdoor applications.

- Available in various sizes and configurations, GI Perforated Cable Trays can be customized according to project requirements.

Salient Features:

- Corrosion-resistant and durable

- Available in multiple materials such as SS (Stainless Steel), GI (Galvanized Iron), and Aluminum

- Provides excellent ventilation and airflow

- Easy to install and maintain

- Suitable for various industrial applications

Applications:

- Electrical installations

- Cable management systems

- Industrial buildings

- Data centers

- Control panel systems

Hot Dip Galvanized Perforated Cable Trays:

- These are made from high-quality steel coated with a thick layer of zinc through a hot-dip galvanizing process.

- This process ensures exceptional corrosion resistance, making them ideal for use in harsh environmental conditions, such as outdoor installations or areas exposed to moisture.

- The perforated design allows for optimal ventilation and heat dissipation around electrical cables.

- These trays are highly durable, offering long-term protection for cables, and are widely used in industries like power plants, data centers, and manufacturing facilities.

Salient Features:

- Robust corrosion resistance due to hot-dip galvanizing

- Ideal for outdoor and harsh environments

- Enhanced ventilation through perforations

- Long-lasting and durable

- Suitable for heavy-duty industrial use

Applications:

- Outdoor electrical installations

- Power plants

- Manufacturing plants

- Data centers

- Industrial cable management systems

Powder Coated Perforated Cable Trays:

- These are made from steel and coated with a layer of powder that is then cured to create a hard, protective finish.

- The powder coating provides an attractive, smooth surface that is resistant to corrosion, chemicals, and abrasion.

- These trays are available in a wide range of colors, making them suitable for aesthetic applications where appearance matters.

- Their perforated design promotes airflow and cooling for the cables, and they are ideal for indoor installations where aesthetic appeal and protection from light corrosion are desired.

Salient Features:

- Attractive and durable powder-coated finish

- Resistance to corrosion, chemicals, and abrasion

- Wide range of color options for aesthetic flexibility

- Easy to install and maintain

- Provides optimal ventilation for cables

Applications:

- Indoor electrical installations

- Commercial buildings

- Data centers

- Control systems

- Office buildings and infrastructure projects